Copyright © Sinor Electronic device Co., Ltd.All Rights Reserved 粤ICP备16001692号 Website construction: 300.cn zhuhai

TAOBAO

Copyright © 中企动力科技股份有限公司 All Rights Reserved 豫ICP备10099324号 网站建设:中企动力 洛阳

Solution

1. The equipment is suitable for the carton model

5465 (1U), 5465 (2U), 7883 (2U), 7885, 7903, 8737

2. Advantages of equipment

1. Save labor costs.

2. Adapt to various models.

3. Fully automatic production.

4. Small footprint.

5. High production efficiency.

Iii. Design and production difficulties (described later in the solution)

The cartons of models 7885, 7903 and 8737 are high and narrow, and easy to collapse.

2. All models are not easy to fold the cover automatically.

3. The height of 5465 (1U) is only 180MM, and the side should be sealed with 100MM adhesive paper. The upper and lower cores interfere with each other.

4. The width of the 7885 model is only 130MM, so it cannot be sealed.

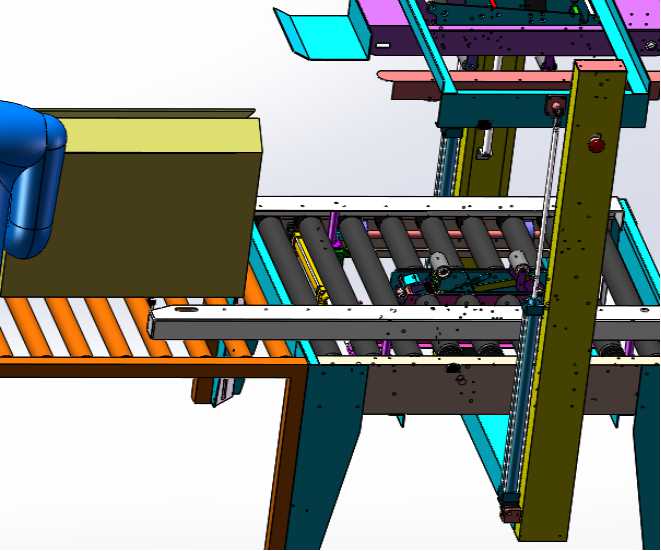

Lenovo Automatic sealing machine details

I. carton clamping mechanism in advance

Problem: vertical cartons are easy to collapse

Problem description: vertical cartons (7885, 7903, 8737) are high and narrow, so they cannot be released manually before the cartons are fully entered into the automatic sealing machine. Otherwise the cartons are at risk of falling down.

Solution: tighten in advance

Solution description: to solve this problem, the X-axis clamping guide rail is lengthened. Hold the product in advance. In this way, after folding the lid of the carton, you can gently push the carton into the guide rail.

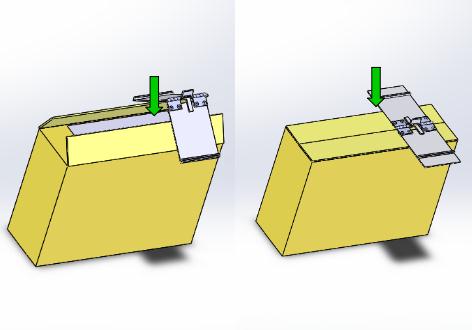

Automatic closing mechanism

Problem: the long side flap is not easy to press

Problem description: the folding cover of the long side of all types of cartons is folded by hand, and cannot be released until the folding cover is completely pressed by the automatic sealing machine. Otherwise there is a risk that the lid will not fit.

Solution: automatic closing mechanism

Program description: this mechanism is installed in front of the "z-axis direction clamping mechanism". When the z-axis automatically clamps down to make the mechanism touch the carton, the long-side cover of the carton will be closed and pressed flat. When the carton is pressed flat, it will touch the induction switch, and then the z-axis will stop pressing. There is no need for manual assistance in the whole process. The carton can be released manually after it enters the guide track of the sealing machine.

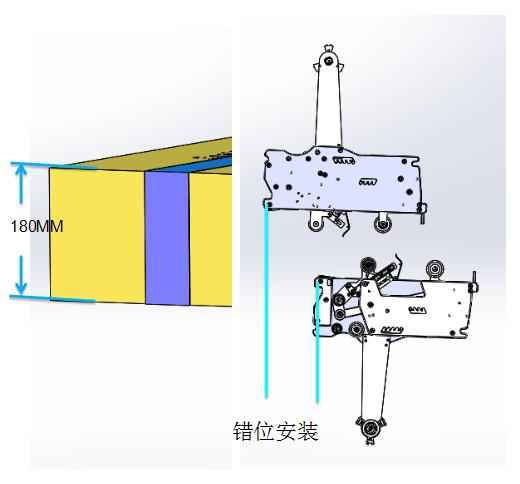

3. Adhesive paper should be prepasted to 100MM long

Problem: the adhesive paper needs to be prepasted 100MM long

Problem description: as the cartons of 5465 (1U) are only 180MM high, the adhesive paper needs to be prepasted (side pasted) 100MM long. Therefore, the upper and lower core will interfere with each other. (as shown on the left)

Solution: upper and lower core dislocation installation

Solution description: in order to solve this problem, the core of the automatic sealing machine will be installed by dislocation. So up and down the core will not interfere. (as shown on the right)

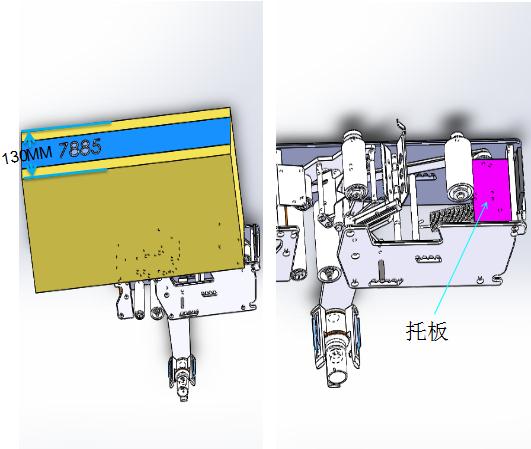

The narrowest cartons cannot be sealed

Problem: narrow cartons cannot be sealed

Problem description: as the 7885 cartons are only 130MM, the smallest core width is 110MM. In addition, the installation position of the machine core is only 115MM. Therefore, this kind of cartons may not be able to be sealed.

Solution: add a tray to the core

Solution description: to solve this problem, we will install the rear end of the sealing core with a supporting plate, and the front end with a sealing roller to hold it. In this way, the narrowest cartons can be sealed successfully (the additional pallet is as pink as in the picture on the right).

|

|

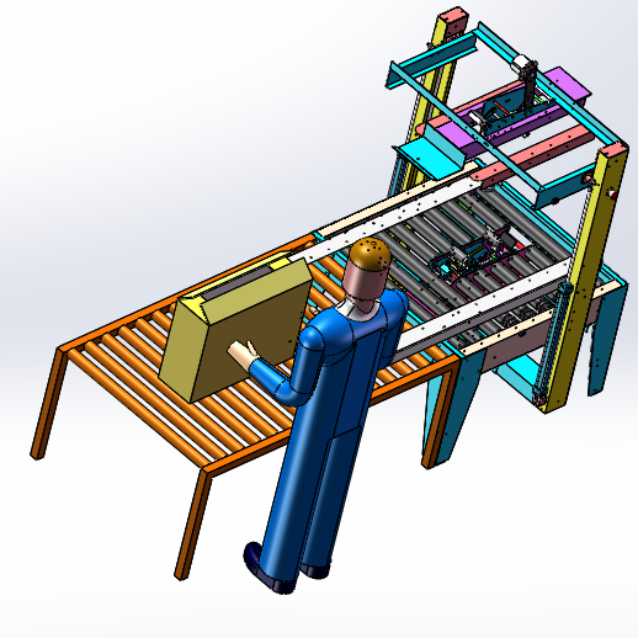

1. Products flow in from the front work station and then are manually packed.

2. The photoelectric sensor at the entrance of the automatic sealing machine senses the X-axis side of the product

And the product pre - folding cover after pushing the automatic sealing machine entrance. Automatic clamping and delivery of products to the automatic clamping and conveying mechanism.